Optimal Timing for Barn Concrete Pouring

Determining the optimal time for barn concrete pourings is essential for ensuring durability and structural integrity. Factors such as weather conditions, temperature, and soil stability influence the success of the pour. Proper planning can prevent issues like cracking, uneven curing, or delays caused by adverse weather.

Ideal conditions include moderate temperatures and low humidity to facilitate proper curing and minimize cracking.

Concrete should be poured when temperatures are between 50°F and 85°F to ensure optimal curing and strength development.

Spring and early fall are preferred seasons due to milder weather, reducing risks associated with extreme cold or heat.

Ensuring the soil is dry and stable prevents uneven settling and foundation issues during and after the pour.

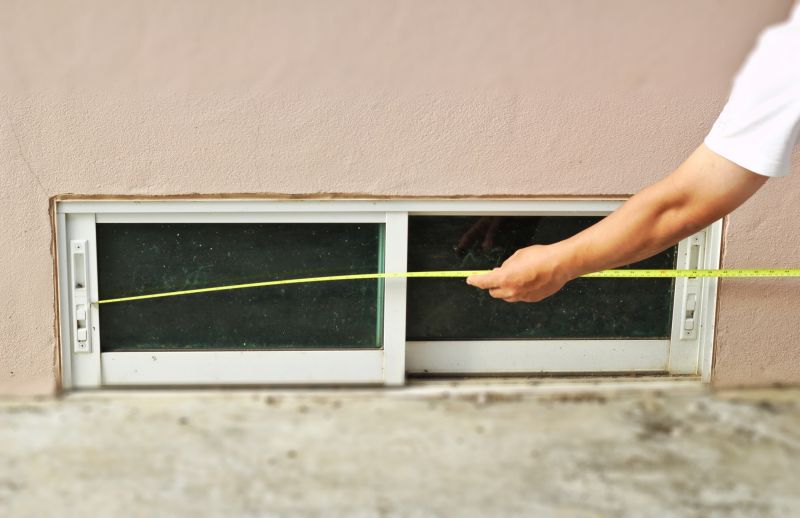

Ways to make Barn Concrete Pourings work in tight or awkward layouts.

Popular materials for Barn Concrete Pourings and why they hold up over time.

Simple add-ons that improve Barn Concrete Pourings without blowing the budget.

High-end options that actually feel worth it for Barn Concrete Pourings.

Finishes and colors that play nicely with Barn Concrete Pourings.

Little measurements that prevent headaches on Barn Concrete Pourings day.

Barn concrete pourings are a critical phase in constructing durable and long-lasting structures. Proper timing ensures the concrete cures effectively, reducing the risk of cracking and structural weaknesses. The process involves preparing the site, mixing the concrete to specifications, and pouring it under optimal conditions. Weather plays a significant role; pouring during mild weather minimizes the risk of thermal stress and moisture-related issues. Accurate scheduling based on seasonal and daily weather forecasts can significantly enhance the quality of the finished structure.

| Aspect | Optimal Conditions |

|---|---|

| Temperature | Between 50°F and 85°F |

| Humidity | Moderate, avoiding high humidity |

| Season | Spring or early fall |

| Weather | Dry days with no rain forecast |

| Soil | Dry and stable ground |

| Time of Day | Morning or late afternoon |

| Forecast | Stable weather forecast for at least 24 hours |

| Preparation | Proper site and material preparation |

A 60-second routine that keeps Barn Concrete Pourings looking new.

A frequent mistake in Barn Concrete Pourings and how to dodge it.

Small tweaks to make Barn Concrete Pourings safer and easier to use.

Lower-waste or water-saving choices for Barn Concrete Pourings.

The short, realistic tool list for quality Barn Concrete Pourings.

Rough timing from prep to clean-up for Barn Concrete Pourings.

Timely and well-planned barn concrete pourings contribute to the longevity and stability of the structure. Proper curing techniques and avoiding extreme weather conditions during the initial curing phase are vital. Regular monitoring of weather conditions and site readiness ensures the concrete achieves its designed strength and durability. Consulting with experienced professionals can assist in scheduling the pour for the most favorable conditions, leading to a successful project outcome.

Interested in scheduling a barn concrete pouring? Fill out the contact form to discuss timing and requirements.